|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#1 |

|

Unusual Piston Shredding Problem

I have gone through 5 modify Pistons (4 ultras 1 original).

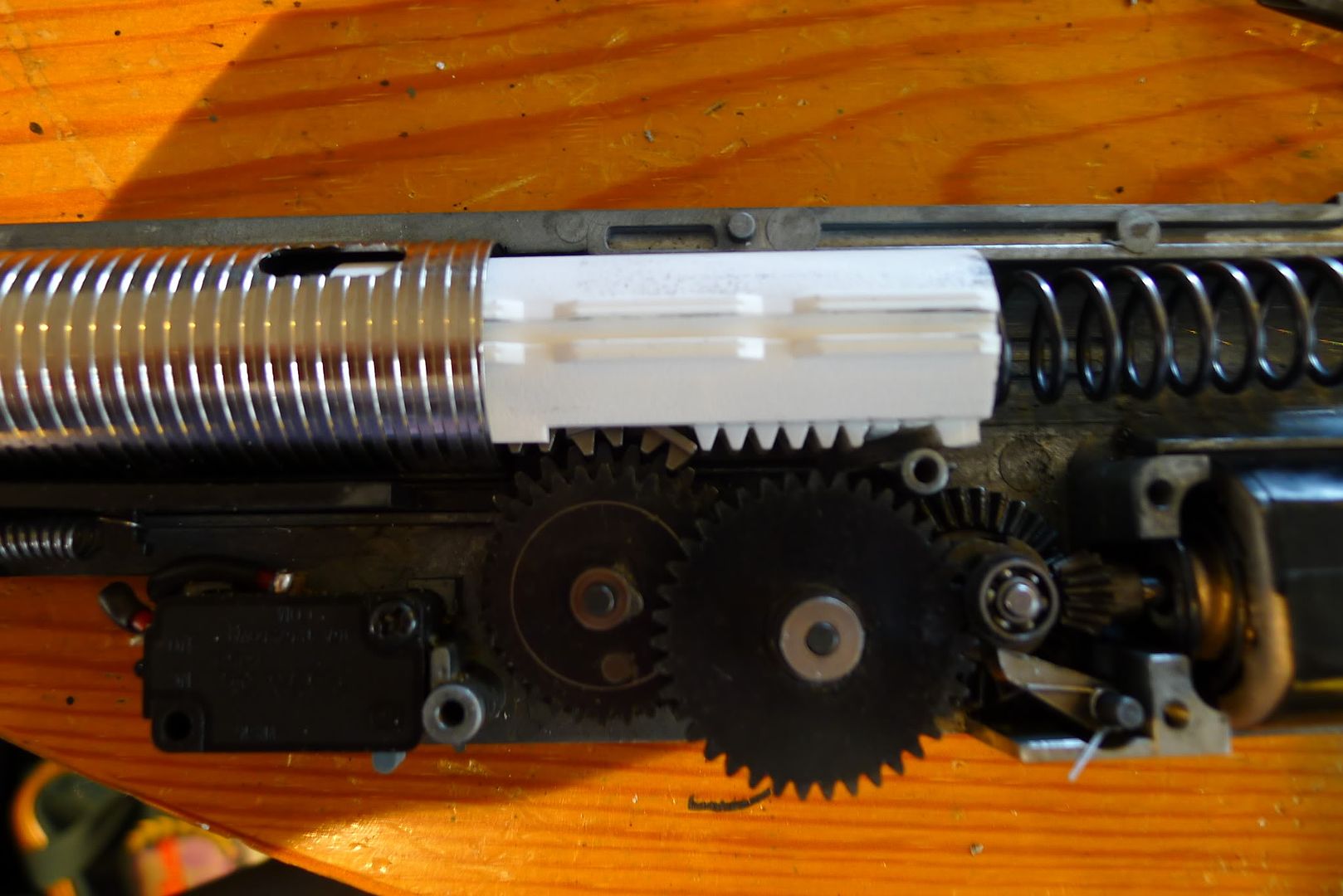

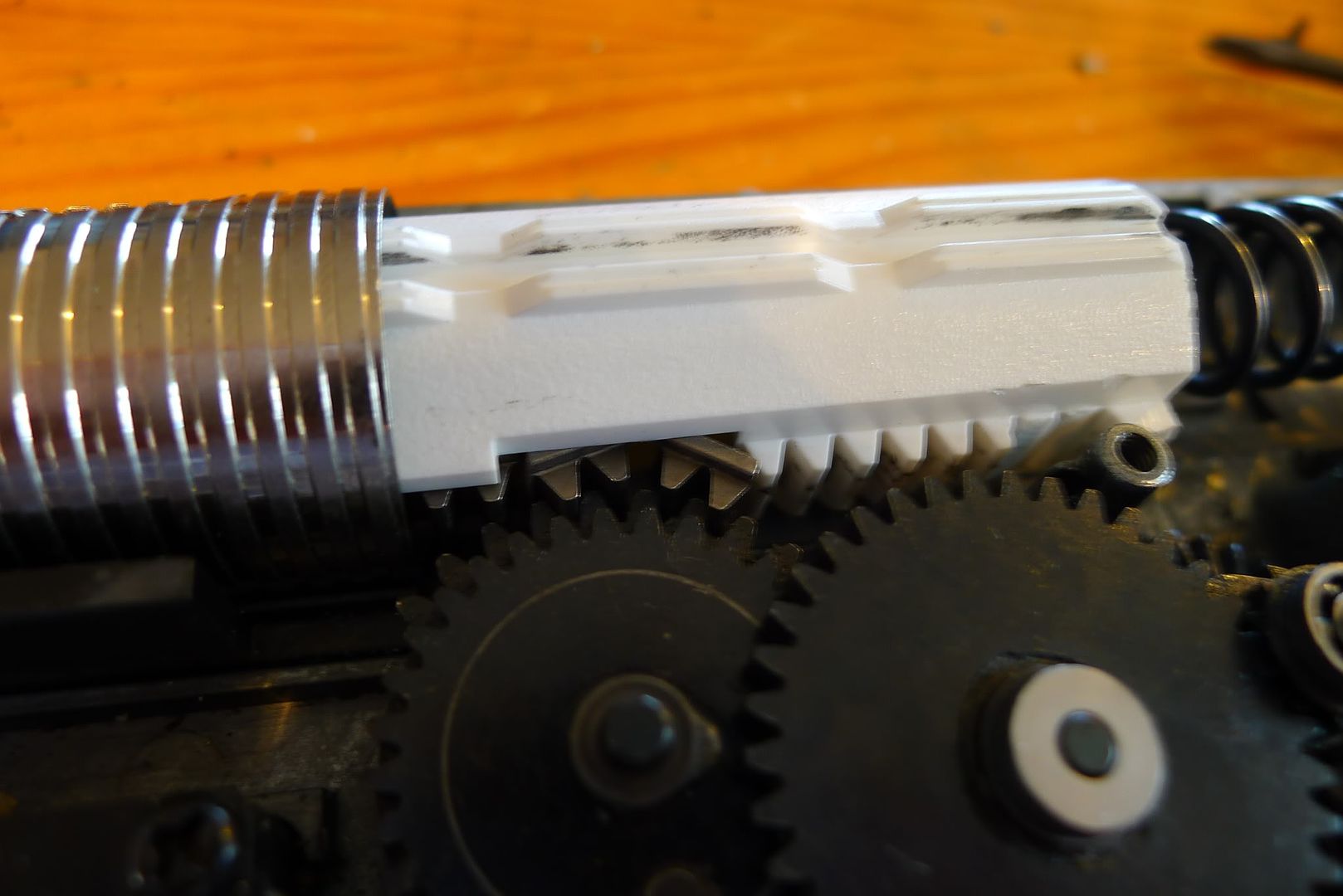

what's unusual about the piston shredding is that it's the middle / metal teeth that are shredding. The first and last teeth appear to be fine except for the 1st piston  About the Gun Ares m60e4 parts that i kept the same for all 5 trials - 5100mAh 7.4 Lipo 25C (40c burst) - Ares upgraded spring guide cylinder head - 8mm Modify bushings / shims - G&P m140 high torque motor - modify piston head - Modify M130+ spring (the mechbox is elongated so the m130+ is more like a m120+ - custom wood spring guide block with the exception of the spring guide block, I have been running with the above parts for the last couple of years And here are the different parts during my 5 Trials (I decided to upgrade to modify high torque gears) Trial 1 - Modify High torque Nano-class gears - non ported cylinder - result: piston shred after 50-100 cycles Trial 2 - Modify High torque Nano-class gears - stock sector gear (even higher torque ratio ratio) - non ported cylinder - result: instantly shredded piston Trial 3 - too pissed off to remember Trial 4 - stock gears - ported cylinder type 1 - result: worked fine 2-300+ cycles there was a noticeable loss in FPS due to the ported cylinder so i decided to switch back to non ported. at this point the gun is set up the way i normal run with it with addition to the wood spring guide block - result shredded piston after 100 cycles or so Trial 5 - stock systema gears - ported cylinder type 1 - result shredded piston after 100+ cycles or so I manged to grab interesting pictures of the last trial failure    I would also like to add that I am using a wooded block to hold the spring guide in place. the original plastic part (propriety ares) broke last month  I have a feeling that this may be the cause? but how? has anybody else experienced a piston shredding problem where only the middle teeth were effected?

__________________

|

|

|

|

|

|

|

#2 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

Well for starters, as per standard PGC mechbox design, your spring guide is actually supposed to be flush with the back of the mechbox. So fix that, try again, then get back to us

There's two ways that rack can be breaking, excessive upwards pressure, or excessive axial pressure. Which, if your piston is jamming on the way back, it would definitely break the rack. |

|

|

|

|

|

#3 | |

|

Quote:

You see the cut-out in the spring guide, that is supposed to be aligned with where your block is currently, not 2" forward. Have you even tried to work the mechbox without a spring? You can't. The gears will still be right where the piston breaks when the piston hits the guide. Have someone make a decent spring guide lock or make one yourself... not out of wood, but a thick (1/8") aluminium plate bent in a U shape to go on both sides of the guide would work perfectly. |

||

|

|

|

|

|

#4 |

|

+1000 to what both of you guys said! the block is the problem!

kos-mos had a really great idea with the u bent shape aluminium plate! it will last forever and hold the spring guide right were its supposed to be!

__________________

member of fire team NOM. my other regular forum: www.toyotanation.com / gen3,gen4 camry |

|

|

|

|

|

|

#5 |

|

just to be clear the mechbox and spring guide are designed with 2x positions

- position 1 - where the spring guide notches are aligned - position 2 - spring guide fully forward (as its seen in the pictures) so the piston is not jamming on the guide, and yes i have run the gear box with out the spring in it many times (I ain't that dumb  ) )in any case I have a feeling it has something to do with the wooden block that's throwing things off balance. the stock ares part had about 1mm of contact on the spring guide whereas the wooden block touches the entire thing I shall try ordering a spare from direct from ares

__________________

|

|

|

|

|

|

|

#6 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

NO.

The back end of the spring guide is forever and always FLUSH with the back of the mechbox, it has only ONE position. The retention pin that's supposed to go in there locks on the groove of the spring guide, NOT the back of it. The spring guide is in too far, when your piston goes back it over-compresses the spring to the point where it becomes solid. THAT is why your piston is breaking. It's impossible to be out of alignment because it's the BORE that aligns the spring guide, it has nothing to do with what's behind it. Case and point, the stock gun works with the 3mm lock engagement on the back, your wooden block with 100% engagement does not. Between the 3 people who posted there's over 8 years fixing guns, you just stripped 5 pistons in a row and you still have no idea what you did wrong. Set your spring guide up properly, try it again, then come back and tell us the result.

Last edited by ThunderCactus; December 11th, 2011 at 23:42.. |

|

|

|

|

|

#7 |

|

__________________

WOLFPACK U-96 Cry Havoc, Let slip the Dogs of War! "Opportunities multiply as they are seized." - Sun Tzu, The Art of War |

|

|

|

|

|

|

#8 |

|

Official ASC Bladesmith

|

I agree with the guys above, I spent a LOT of time working on a certain CA M249 over the years, the spring guide does sit flush with the end of the mechbox......

|

|

|

|

|

|

#9 | |

|

hmmm. I have been running the gun with the stock spring guide stop in the 2nd position for 2 years or so with out incident....until of-course the plastic stop snapped.. pistons were fine tho. I was always under the impression that Ares m60 had the 2 position spring guides for FPS variations

I guess i have been doing it wrong :S I'll try cutting out the block so it fits in the 3mm grove and see how it goes Quote:

__________________

|

||

|

|

|

|

|

#10 |

|

I should also add that when I did run the gun with the spring guide in the second position successfully I was using a m120+ spring (not a m130+)

so after destroying $100 worth of pistons and a few expert explanations everything is starting to make sense now I'll let you guys know how things turn out

__________________

|

|

|

|

|

|

|

#11 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

Well the reason your stop broke in the first place is because you had the spring guide too far forward lol

|

|

|

|

|

|

#12 |

|

Alright I got a new piston thanks to -Trooper- and everything seems to be in working order

I sure feel dumb since it took me so long / many attempts to figure it out so I realized with he original Ares 2 stage design, the 2nd position was not how I had it with ghetto wooden block ( don't know what the hell I was thinking when I Dremeled out that wooden block) a simple check as per ThunderCactus diagram would have saved me a lot of pistons  why didn't i do this check in the first place!! so easy to tell that there is pretty much zero room between the piston and spring guide during compression. Dam it.... I'm.... slow.... hah modified the wooden block so the slot / spring guide sits flush with the gear box.  I didn't like how it was sitting in the gear box. There wasn't enough contact and would most likely slip out due to vibration. so I dropped in nut a bolt instead. The spring guide does not sit flush to the gear box, but it's where the 2nd position would be with the original ares 2 step spring guide. there is still plenty of room between the spring guide and piston during compression so it isn't over compressing like before.   Don't know why I didn't think of using a nut and bolt in the first place either :banghead: I've cycled the mech box about 350 - 400rnds and everything seems fine. real test will be when i game it, but I'm quite confident that its fixed now. So Thanks ThunderCactus & Co. for the advice / explanations!!

__________________

|

|

|

|

|

|

|

#13 |

|

aka coachster

|

If you are worried about the wood block slipping, I wouldn't have cut the block with the grain in that direction. But I wouldn't have used wood to start with. Is that bolt going through the spring guide or sitting behind it?

|

|

|

|

|

|

#14 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

Awesome. Glad we could help

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|